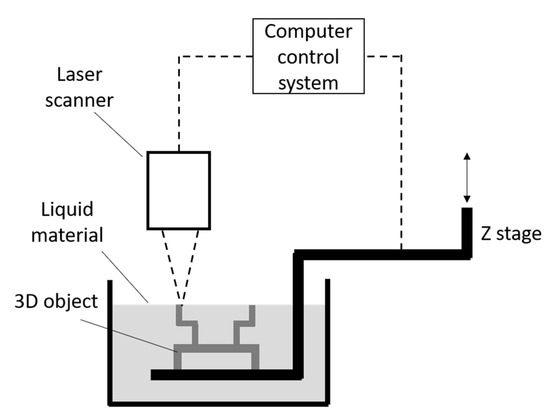

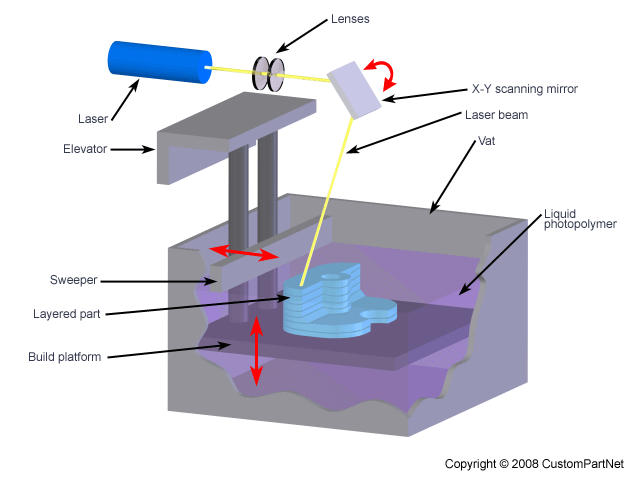

After a layer is imaged on the resin surface the build platform shifts down and a recoating bar moves across the platform to apply the next layer of resin. Stereolithography SLA is an additive manufacturing process that belongs to the Vat Photopolymerization family.

What S The Difference Between Stereolithography And Selective Laser Sintering Machine Design

The materials used in SLA are photosensitive thermoset polymers that come in a liquid form.

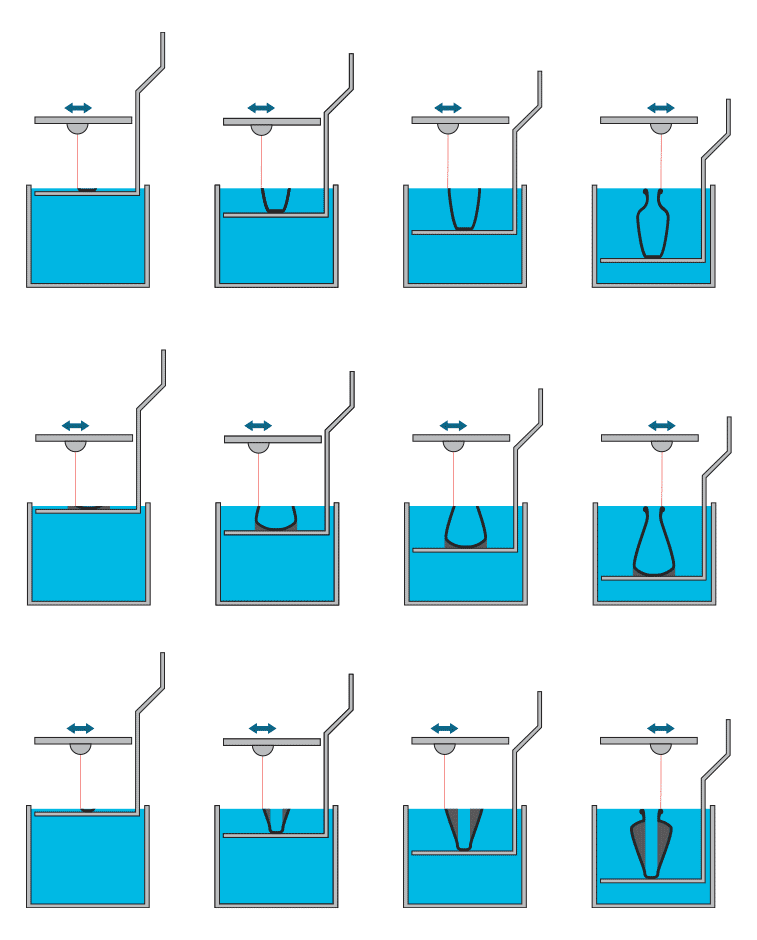

In the stereolithography process the build material is. This is because SLA printers cannot be dual extruder printers like with FDM. In this research a suspension-enclosing projection-stereolithography process is developed to overcome this challenge. Being the earliest form of additive manufacturing stereolithography SLA fabricates 3D objects by selectively solidifying the liquid resin through a photopolymerization reaction.

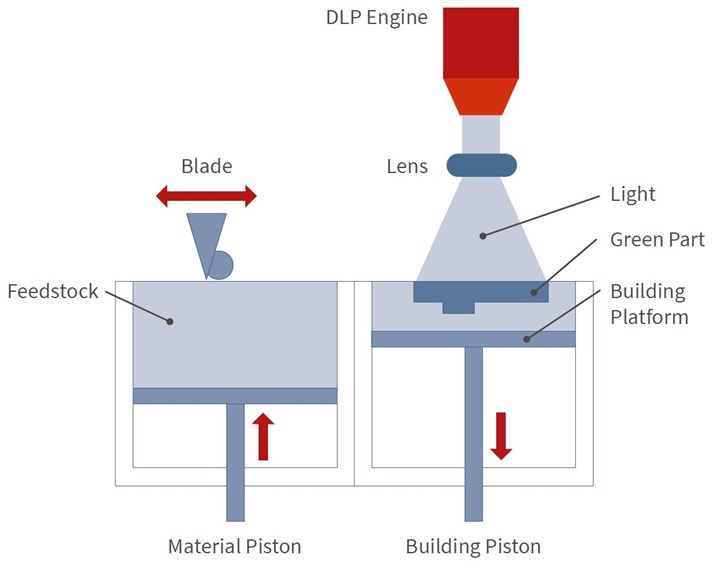

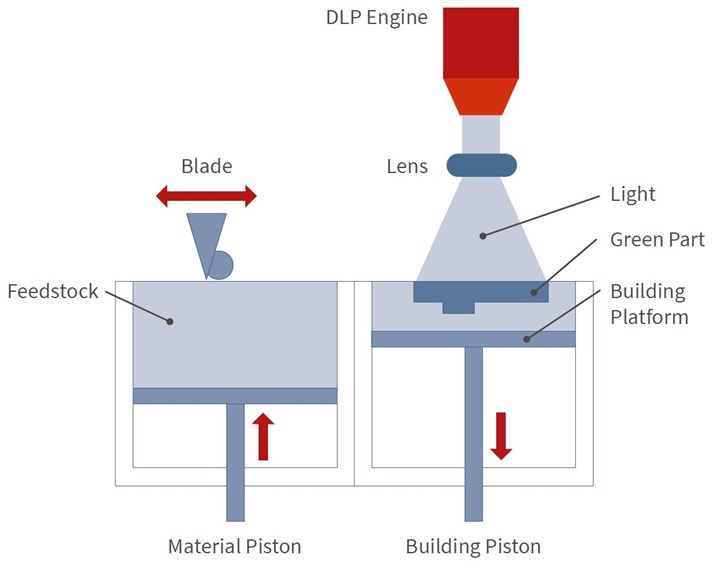

Two main SL techniques namely scanning SL and projection SL have been developed depending on the beam delivery system. And is based on layer-by-layer polymerization of photosensitive resin using ultraviolet UV light. A multi-material stereolithography MMSL machine was developed by retrofitting components from a commercial 3D Systems 25050 stereolithography SL machine on a separate stand-alone system and adapting the components to function with additional components required for MMSL operation.

Stereolithography is an additive manufacturing process in which liquid photopolymer resin is cross-linked and converted to solid. Stereolithography SLA was the first largely accepted rapid prototyping technique which was first introduced in the early 1980s. Checking 3D CAD data De-powdering loose material Dip in a binder to strengthen the part.

Unlike FDM these supports are always made of the same material as the object being 3D printed. Stereolithography is an imaging progression which is used to create unique 3D-printed objects. Stereolithography gained particular attention due to the low cost of both available machines and suitable polymeric materials to be processed.

Stereolithography belongs to a family of additive manufacturing technologies known as vat photopolymerization commonly known as resin 3D printing. The main restriction to the adoption of this technique comes from the obtainable dimensional accuracy that depends not only on design but also on process set-up. In SLA an object is created by selectively curing a polymer resin layer-by-layer using an ultraviolet UV laser beam.

One PP-like material and one molded PP thermoplastic are compared across four material property categories. The implementation of stereolithography is fair though there are many different variations which it is used. The Stereolithography Process The Stereolithography process was first developed in 1986 when Chuck Hull founder of 3D Systems created a system by which 3D CAD data is converted into physical models layer by layer in a vat of UV curable liquid resin.

The stereolithography SLA process and its methods are introduced in this chapter. A laser which generates a small intense beam of ultraviolet UV energy is moved by the machines optical scanning system across a vat of photosensitive liquid polymer building your part layer by layer. The process is repeated layer by layer until the build is complete.

Stereolithography unlike Selective Laser Sintering or Binder Jetting uses supports. After a layer is imaged on the resin surface the build platform shifts down and a recoating bar moves across the platform to apply the next layer of resin. Stereolithography models allow us to do production intents within days.

Stereolithography was the first commercial SFF process developed by 3D Systems Inc. These machines are all built around the same principle using a light sourcea laser or projectorto cure liquid resin into hardened plastic. The ability to fabricate objects with high accuracy as well as a wide variety of materials brings much attention to stereolithography.

The fabrication of digital material requires frequent resin changes during the building process. Metal plating is a secondary process that adds a thin copper-nickel coating that provides the look feel and strength of a. Q24 Which of the following is the process of the pre-processing stage.

Q26 Which of the process the input material is in liquid form. This process uses a high-yield-stress ceramic slurry as the feedstock material and exploits the elastic force of the material to support overhanging features without the need for building additional support structures. Q25 From the following in which process the input material is in solid form.

The MMSL machine required construction of a new frame and the development of a. After establishing SLA as pertaining to the high-resolution but also high-cost spectrum of the 3D printing technologies different classifications of SLA processes are presented. Newly built parts are taken out of machine and into a lab where solvents are used to remove any additional resins.

SLA SLS FDM MJM. Materials with various concentrations and structures to produce a solid object with desired material characteristics. The unique 3D printing machine also referred to as stereolithography apparatus converts liquid plastic into solid objects.

These supports require a solvent to remove excess resin such as isopropanol. Laser-based SLA and digital light processing DLP as well as their specialized techniques such as two-photon polymerization TPP. The process is repeated layer by layer until the build is complete.

The process presented in this paper attempts to address the related. Newly built parts are taken out of machine and into a lab where solvents are used to remove any additional resins.

Stereolithography Process An Overview Sciencedirect Topics

Stereolithography Encyclopedia

Stereolithography An Overview Sciencedirect Topics

Stereolithography 3d Printing Technology I Materialise

Stereolithography Sla 3d Printing Service Instant Quoting

Schematic Of Stereolithography Process Download Scientific Diagram

Stereolithography For Metals Produces Detailed Parts Additive Manufacturing

Sketch Of The Stereolithography Process Download Scientific Diagram

Lpe Stereolithography Process High Quality Prototypes In Days

Stereolithography Process An Overview Sciencedirect Topics

Schematic Representation Of Stereolithography Sla Process Image Download Scientific Diagram

Stereolithography Process An Overview Sciencedirect Topics

Stereolithography An Overview Sciencedirect Topics

An Example Of An Advanced Am Process Stereolithography Sla The Download Scientific Diagram

Rapid Prototyping Stereolithography Sla

How Stereolithography Sla 3d Printing Works Manufactur3d

Komentar

Posting Komentar